SCADA helps industrial organizations preserve effectivity, talk system points to mitigate downtime, and course of knowledge to make smarter selections.

Many industrial vegetation, distant websites, and manufacturing flooring used to depend on personnel to manually monitor and manually management electrical tools by means of analog dials and push buttons.

Because the distant websites and industrial flooring started to scale out, they wanted higher options to regulate their electrical tools from lengthy distances. Some organizations began to make use of timers and relays to supply a greater degree of supervisory management.

Though timers and relays remedy massive issues, they supply restricted automation performance. Once more, timers and relays have been tough to configure. The management panels and fault-find took up more room. Therefore, extra points started to come up.

A technology- ‘ SCADA’- was launched to unravel these sorts of points.

The rise of PLCs and microprocessors throughout the begin of SCADA helps organizations monitor and management automated processes greater than earlier than.

On this article, I’ll focus on SCADA, its makes use of, options, parts, varieties, and extra.

Let’s begin!

What Is SCADA?

Supervisory Management and Knowledge Acquisition (SCADA) is a kind of utility that permits industries to regulate their industrial processes, corresponding to gathering knowledge from distant areas in actual time to regulate the circumstances of kit. It affords many instruments wanted to deploy data-driven selections in real-time.

SCADA has solved many industrial monitoring and controlling processes for the reason that Seventies.

Within the late 90s and early 2000s, SCADA adopted a change by grabbing open system structure in addition to communication protocols, which aren’t vendor-specific. This leveraged communication applied sciences like Ethernet, which allowed programs to speak with different distributors, elevating the constraints in older SCADA programs.

Trendy SCADA programs enable industrial flooring to entry real-time knowledge from wherever on the earth. This entry permits companies, people, and governments to make higher selections on tips on how to improve their processes. Will probably be not possible to gather adequate knowledge with out SCADA software program.

As well as, fashionable SCADA designer software program has Fast Software Improvement (RAD) capabilities. This lets customers design functions simply even with zero data of software program improvement.

The introduction of contemporary IT practices and requirements, corresponding to web-based functions and SQL into SCADA software program has improved the safety, reliability, productiveness, and effectivity of SCADA programs.

The large benefit of utilizing SQL databases is that it makes the method of integrating into ERP and MES programs simpler, permitting knowledge to circulation by means of the complete group seamlessly.

Thus, SCADA is a system of {hardware} and software program components that permit industrial organizations:

- Management industrial processes at distant areas or domestically

- Monitor, accumulate, and course of knowledge in real-time

- Work together instantly with units, corresponding to pumps, valves, sensors, motors, and extra, by means of Human Machine Interface (HMI software program)

- File all of the occasions in a log file

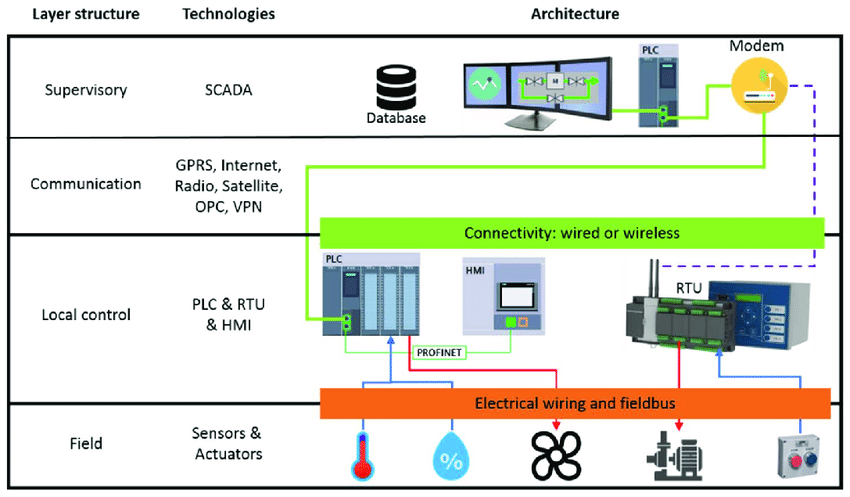

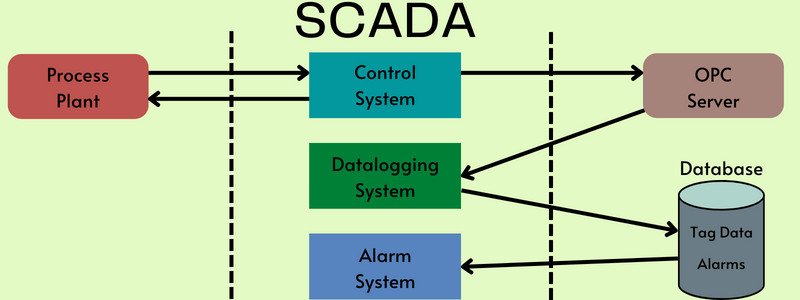

The fundamentals of its structure start with Distant Terminal Models (RTUs) and Programmable Logic Controllers (PLCs). These two are the microcomputers that talk with a variety of objects, corresponding to sensors, finish units, HMIs, and manufacturing facility machines. RTUs and PLCs route the information from the objects to the computer systems utilizing SCADA software program.

Nonetheless, SCADA software program processes, shows, and distributes the information, serving to workers and operators analyze the knowledge and make vital selections.

For instance, the SCADA system shortly addresses an operator concerning a batch of merchandise that present errors. The operator pauses the operation, views the system knowledge by means of HMI, and determines the reason for the problem. The operator then critiques the knowledge and discovers that ‘Machine 4″ shouldn’t be working.

This fashion SCADA system helps the operator in figuring out the problem, resolving it on time, and forestall additional loss.

Parts of a SCADA System

SCADA programs have varied parts which can be deployed within the area to collect knowledge in actual time. These parts allow the gathering of knowledge and enhancement of commercial automation.

Let’s focus on every element intimately.

#1. Sensors and Actuators

A sensor is a tool or system that detects enter capabilities from industrial processes. An actuator is a tool that controls the mechanism of commercial processes. Sensors capabilities like a meter or gauge that shows the standing of the machine.

An actuator acts like a dial, management, or swap that can be utilized to regulate the machine. Each are monitored and managed by SCADA area controllers.

#2. SCADA area controllers

The sphere controllers interface instantly with actuators and sensors. There are two classes on this:

- Distant Telemetry Models (RTUs) interface with sensors to collect telemetry knowledge after which ahead the identical to a main system for the following motion.

- Programmable Logic Controllers (PLCs) interface with the actuators to keep up and management industrial processes based mostly on present telemetry that the RTUs accumulate.

#3. SCADA supervisory computer systems

Supervisory computer systems management all processes associated to SCADA. They’re used to gather knowledge from area units and to ship instructions to the units to be able to management industrial processes.

#4. HMI Software program

This software program supplies a system that confirms and presents knowledge from the SCADA area units. It additionally permits operators to grasp and modify the standing of the SCADA-controlled processes.

#5. Communication infrastructure

The communication infrastructure permits SCADA supervisory programs to speak with the sector controllers and area units. This additionally permits SCADA programs to collect knowledge from the sector units and management these units.

Options of SCADA Techniques

SCADA programs embrace particular options for particular functions or industries, and a lot of the programs assist the next options:

- Knowledge acquisition: It’s a basis of SCADA programs the place sensors collect knowledge and ship the identical to area controllers. In return, the sector controllers feed knowledge to the SCADA computer systems.

- Distant management: It’s achieved by the management of the sector actuators, which is predicated on the information gathered from area sensors.

- Networked knowledge communication: It permits all SCADA capabilities. Knowledge gathered from sensors are transmitted to the SCADA area controllers, which then talk with the SCADA supervisory computer systems. The distant management command is transmitted again to the actuators from the supervisory computer systems.

- Knowledge presentation: It’s achieved by means of HMIs that characterize present and historic knowledge wanted by the operators to be able to run the SCADA system.

- Alarm: It alerts the operators of the numerous circumstances within the SCADA system. It may be configured simply to inform operators when the processes are blocked, some programs are failing, or different facets want stopping, beginning, or adjustment.

- Actual-time and historic knowledge: Each are important elements of the SCADA system. This may allow customers to trace the efficiency of the present situation in opposition to historic traits.

- Reporting: This contains stories on course of efficiency, system standing, and customised stories for particular makes use of.

Working of SCADA

The SCADA programs carry out some capabilities, together with knowledge acquisition, knowledge communication, info/knowledge presentation, and monitoring/management. These capabilities are carried out by the parts of the SCADA, corresponding to sensors, RTUs, controllers, a communication community, and many others.

The sensors are used to collect important knowledge, and RTUs are used to ship this knowledge to the controller to show the system’s standing. In response to the standing, the consumer provides the command to different parts to carry out their perform. A communication community does this perform.

Right here, we’ll focus on every perform to grasp the working precept of the SCADA programs.

Knowledge Acquisitions

An actual-time SCADA system consists of many sensors and parts to collect info and ship the information for additional processing.

For instance, a few of the sensors measure the water circulation from a reservoir to the water tank, and different sensors measure the strain because the water is launched from the reservoir. Right here sensors purchase various kinds of knowledge to grasp if all of the processes are going easily.

Knowledge Communication

The SCADA programs use a wired community to gather and switch knowledge between customers and units. Actual-time SCADA functions use parts and sensors which can be managed remotely. It makes use of web communications as nicely. Since relays and sensors usually are not in a position to talk, RTUs are used to speak community interfaces and sensors.

Knowledge Presentation

The conventional networks include indicators which can be seen to be able to management. In real-time SCADA functions, there are quite a lot of alarms and sensors that are not possible to handle at a time. The SCADA system makes use of HMI to supply all the information gathered from varied sensors.

Monitoring and Management

The SCADA system makes use of varied switches to function units and shows the standing of the managed space. Any half will be turned on/off from the station through the use of these switches. The SCADA utility is carried out to work with none human intervention mechanically. Solely in crucial conditions will or not it’s dealt with by a human.

Kinds of SCADA

SCADA programs are categorized into 4 varieties, together with Monolithic SCADA programs, Distributed SCADA programs, Networked SCADA programs, and IoT SCADA programs.

#1. Monolithic SCADA Techniques

The early or first-generation SCADA programs are often known as Monolithic SCADA programs. On this, minicomputers are used. The event of monolithic SCADA programs will be accomplished when a typical community service shouldn’t be obtainable. The design of this method is like an unbiased system, which implies the design of 1 system doesn’t should be associated to a different system.

The information will be collected from the RTUs through the use of a backup mainframe. The essential perform of first-generation programs is restricted to flagging processes and monitoring the sensors.

#2. Distributed SCADA Techniques

Distributed SCADA programs are additionally known as second-generation programs. The management capabilities are distributed throughout varied programs by connecting with a LAN. The management operations are carried out by command processing and sharing real-time knowledge.

On this system, the fee and dimension of every station are lowered, however there are not any constant community protocols.

#3. Networked SCADA Techniques

The networked SCADA programs are often known as third-generation programs. The communication community of current SCADA programs works through WAN system by means of telephones or knowledge strains.

The information transmission among the many nodes is completed through the use of Fiber-optic or Ethernet connections. This makes use of PLC to regulate, monitor, and management the flagging operations as soon as there’s a necessity.

#4. IoT SCADA Techniques

IoT SCADA programs are often known as fourth-generation programs. Right here, the system’s infrastructural price is minimized by implementing IoT through cloud computing. Integrating and sustaining these programs is less complicated than others.

In a real-time system, the situation of the parts or units will be reported simply by means of cloud computing.

Advantages of SCADA

The advantages of SCADA programs are as follows:

- Scalability: Trendy SCADA programs are scalable for a number of causes, corresponding to higher availability of supported software program and {hardware}, use of cloud computing to be able to meet workload demand, and many others.

- Interoperability: Trendy SCADA programs don’t depend on proprietary software program and {hardware}, leading to zero vendor lock-in.

- Communications: SCADA helps fashionable communications protocols that allow higher accessibility to the Scada controls and knowledge.

- Assist: Trendy SCADA programs are nicely supported by the distributors. Using open networking requirements, fashionable software program improvement platforms, and industrial off-the-shelf {hardware} makes third-party distributors extra accessible as nicely.

Limitations of SCADA

Among the limitations of a SCADA system are the next:

- It comes with advanced {hardware} items and dependent modules.

- It wants programmers, expert operators, and analysts for upkeep.

- Set up price is excessive.

- Many speculate that SCADA may help enhance the unemployment price.

Use Circumstances of SCADA

SCADA is used on many industrial flooring to help in managing and automating industrial processes and functions since these processes have turn out to be advanced and cumbersome for human management and monitoring.

SCADA is helpful for processes that may be managed and monitored remotely, particularly within the case the place it’s fairly doable to attenuate waste and improve effectivity.

The widespread business examples of SCADA automation are as follows:

- Oil and gasoline refining operations

- Electrical energy technology and distribution

- Chemical manufacturing

- Telecommunications infrastructure

- Fabrication and associated processes

- Transportation and transport infrastructure

- Utility infrastructures, corresponding to water and waste management

- Meals and beverage processing

With the assistance of SCADA expertise, these processes will be tracked carefully and managed correctly to enhance efficiency over time. Efficient programs lead to vital financial savings of time and money.

The trendy world is utilizing SCADA programs of some form. Some examples will be – sustaining refrigeration programs, guaranteeing manufacturing security at a refinery, getting high quality requirements at a wastewater therapy plant, monitoring power use at your private home, and extra.

The right way to Implement a SCADA Resolution

You will need to contemplate these vital steps whereas implementing a SCADA system:

- Outline what you wish to monitor clearly and perceive it

- Decide what kind of knowledge you wish to accumulate and the way

- Add gateways to affix current knowledge assortment factors

- Create knowledge assortment factors if required

- Centralize the information to the monitoring location you need

- Map knowledge within the SCADA utility of your selection

- Add visualizations of controls and knowledge processes

- Outline guidelines and automation

As soon as you’re accomplished with the whole lot, SCADA software program takes care of the remaining. It helps you work together with the power, alert points, inform predictive upkeep, and provide management over the tools.

Conclusion

SCADA affords an environment friendly method to management and handle industrial processes and knowledge and detect system points and talk them for fast fixation. So, as a substitute of doing the whole lot manually or losing your money and time, you may automate these processes utilizing a SCADA system.

SCADA is carried out with particular objectives. So, if you want to implement it in your organization, decide your wants and automate the processes accordingly.